Understanding Wheat Drying Temperature for Optimal Grain Quality

Wheat drying temperature plays a crucial role in the agricultural sector, especially in determining the quality of harvested grains. As wheat is one of the most widely cultivated cereal grains, it is essential for farmers to understand the intricacies of drying processes to enhance grain quality, prevent spoilage, and optimize their yield. In this comprehensive article, we will delve into the factors affecting wheat drying, the significance of optimal drying temperatures, and how effective farm equipment repair can ensure a successful drying process.

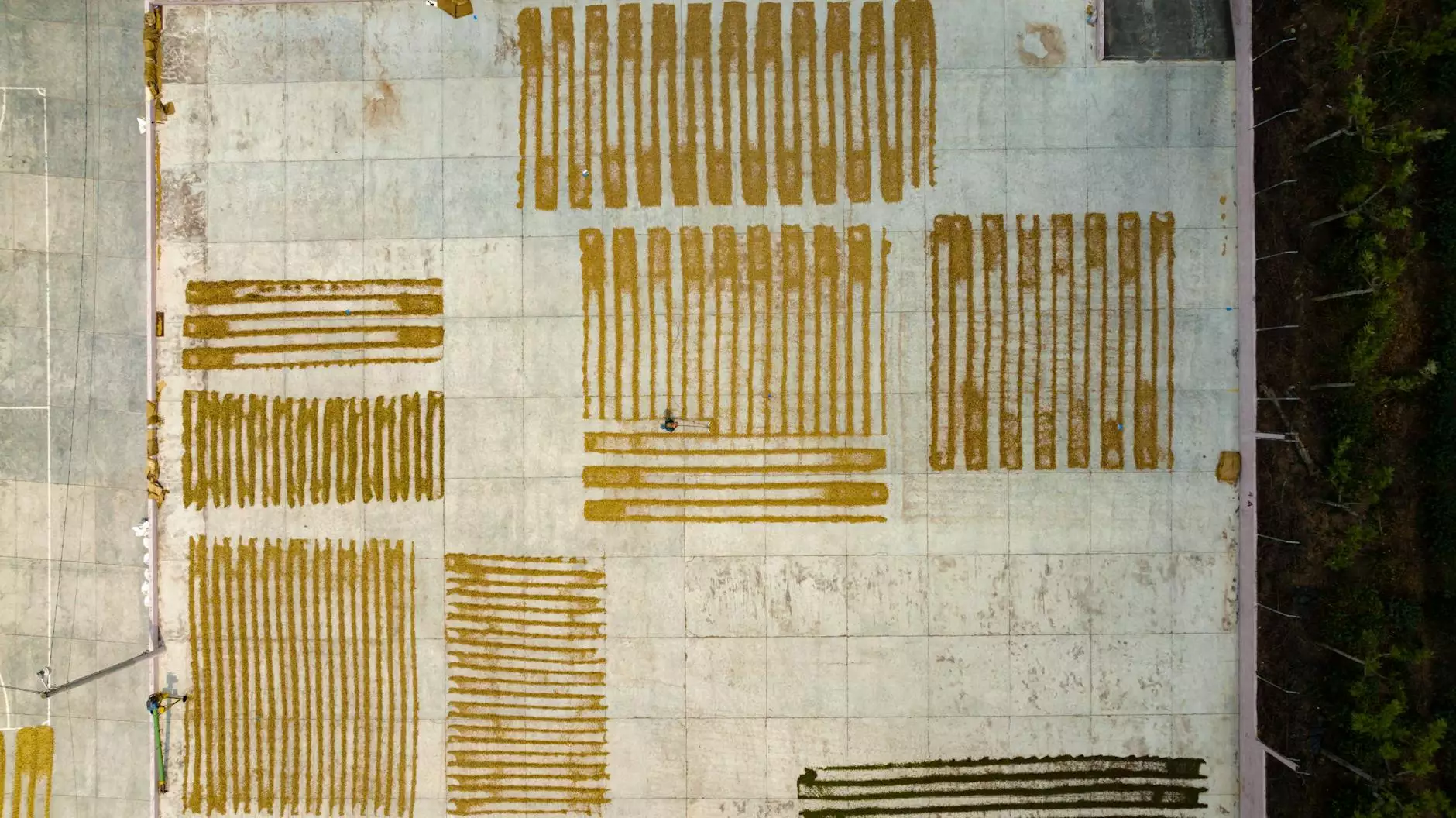

The Importance of Wheat Drying Temperature

The drying process is essential in preventing mold growth, maintaining quality, and extending the shelf life of wheat. The right wheat drying temperature not only influences the moisture content of the grains but also affects their nutritional quality and marketability. Let’s explore why getting the temperature right matters:

Preventing Spoilage

Grains, especially wheat, are prone to spoilage due to excess moisture. High moisture content (usually above 14%) can lead to fungal growth and a decrease in grain quality. When the drying process employs the right temperature, the moisture is effectively reduced, minimizing risks of spoilage.

Enhancing Nutritional Value

The nutritional profile of wheat can be compromised if the drying process is not adequately managed. Proper wheat drying temperature ensures that essential nutrients, such as proteins and vitamins, are preserved for optimal consumption and market value.

Economic Considerations

For farmers, every aspect of grain handling contributes to the bottom line. Inadequate drying can lead to significant losses due to damaged grains and reduced selling prices. Investing in the right equipment and mastering the necessary techniques to control wheat drying temperatures can lead to substantial economic benefits.

Factors Affecting Wheat Drying Temperature

There are several factors to consider when determining the appropriate wheat drying temperature. These include environmental conditions, equipment capabilities, and grain characteristics:

Environmental Conditions

- Humidity Levels: High ambient humidity can slow down the drying process, necessitating the need to increase temperature settings to achieve effective moisture removal.

- Weather Patterns: Seasonal changes can affect drying schedules. Understanding regional weather patterns is crucial for farmers.

- Airflow: Adequate airflow helps in efficient drying but needs to be balanced with temperature to avoid crop damage.

Equipment Capabilities

The type of equipment used for drying wheat plays an important role in controlling the drying temperature:

- Drying Systems: Different systems have varying capacities to maintain and control temperature. Understanding your equipment's specifications will help you make informed decisions.

- Repair and Maintenance: Regular maintenance of drying equipment is necessary to ensure consistent performance. Effective farm equipment repair can prevent breakdowns during critical drying periods.

Grain Characteristics

The characteristics of the wheat itself will also dictate the drying temperature:

- Moisture Content: Newly harvested wheat typically has a higher moisture content and will require a higher drying temperature initially.

- Kernel Integrity: Different wheat varieties may react differently to heat; therefore, knowing your grain is crucial.

Recommended Wheat Drying Temperatures

While the ideal wheat drying temperature can vary based on the factors mentioned earlier, general recommendations exist:

- Initial Drying: Start drying new harvest wheat at higher temperatures (up to 130°F or 54°C) to quickly reduce moisture levels.

- Subsequent Drying: Once moisture falls below 16%, lower temperatures (about 110°F or 43°C) are advisable to preserve grain quality.

- Storage Preparation: Final drying stages should aim for below 14% moisture content, which may require additional temperature control.

Best Practices for Wheat Drying

Implementing best practices in wheat drying is essential for achieving optimal results. Here are some tips for farmers:

1. Monitoring Moisture Levels

Regularly test the moisture content of your wheat using moisture meters. Knowing the current moisture levels helps you adjust temperatures effectively during drying.

2. Adjusting Airflow

Utilize adjustable fans to optimize airflow during the drying process. This not only enhances drying efficiency but also helps maintain consistent temperature levels.

3. Regular Equipment Maintenance

Ensure that drying equipment is functioning optimally by adhering to a maintenance schedule. This prevents disruptions and ensures that the wheat drying temperature can be controlled accurately.

4. Training and Skills

Anyone involved in the drying process should receive adequate training on the operation of drying equipment and best practices in grain management.

Understanding the Role of Farm Equipment Repair

In maintaining the drying process, it's imperative to have reliable farm equipment. Regularly scheduled repairs and maintenance help ensure that your drying equipment operates effectively during critical harvesting times. Here are some key aspects of farm equipment repair:

The Importance of Timely Repairs

Breakdowns in drying equipment can lead to significant losses. Prioritizing timely repairs can help prevent these disruptions, enabling farmers to dry their wheat at the right time and temperature.

Quality Parts and Service

Utilizing quality parts during repair work ensures longevity and reliability of your equipment. Partnering with reputable service providers for farm equipment repair guarantees that your equipment remains in top condition.

Emergency Repair Services

Having access to emergency repair services can be a game-changer during harvest seasons. This minimizes downtime and can save you from significant monetary losses.

Conclusion

Understanding the significance of wheat drying temperature and effectively managing the drying process is fundamental for every wheat farmer. By considering environmental factors, knowing the capabilities of your equipment, and following best practices, you can ensure high-quality harvests and maintain good market value.

Effective farm equipment repair is essential to support this process, ensuring that your drying machinery operates reliably throughout the harvest. In a competitive agricultural landscape, being educated on these factors not only enhances yield quality but also strengthens the financial viability of your farming operations.